Baskets & Shafts

The Rotating Basket

The rotating basket

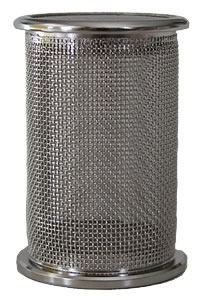

Adopted in 1970 the rotating basket method of dissolution testing was the first official method. Essentially it consisted of an approximately 1 inch (25.4mm) × 1 3/8 inch (34.925mm) stainless steel, 40-mesh wire basket rotated at a constant speed between 25 and 150rpm. This method is now called Apparatus 1.

Standard 40 Mesh Basket

Suppository Basket

The apparatus consists a metallic drive shaft connected to the cylindrical basket. The basket is positioned inside a vessel made of glass or other inert, transparent material. The temperature inside the vessel is kept at a constant temperature by being placed inside a water bath or heating jacket. The solution in the vessel is stirred smoothly by the rotating stirring element.

Baskets and basket shafts should be serialised where possible and the serial number noted for each test.

Other types of basket exist for specific applications. For example, suppository baskets are normally manufactured from plastic or PTFE and have vertical slits to facilitate the dissolution.

Japanese baskets are sometimes confused with dissolution baskets although they are actually sinkers. Products manufactured under the JP may require the use of this basket.